|

|

|

{Page 27}

USDA-ARS Grazinglands Research Laboratory, 7207 West Cheyenne St., El Reno, OK 73036

Redlands Community College, 1300 S. Country Club Road, El Reno, OK 73036

Texas A&M Research and Extension Center, 1619 Garner Field Rd., Uvalde, TX 78801

USDA-ARS Grazinglands Research Laboratory, 7207 West Cheyenne St., El Reno, OK 73036

Redlands Community College, 1300 S. Country Club Road, El Reno, OK 73036

A new system for finishing beef calves on small farms in Oklahoma was compared to the currently used total confinement system. The objective of the experiment was to provide Oklahoma beef cattle producers with an option that would use available resources more efficiently and increase farm enterprise returns. Beef calves were born in the spring, weaned in the fall, and transported to El Reno, Oklahoma to graze winter wheat or dormant native prairie. In the spring, these calves grazed cool season grass pastures. In June, they were blocked by breed, source, and any previous treatments. They were then randomly assigned within their block to a conventional total confinement finishing system or to a new system where calves grazed warm season grass pastures with ad libitum access to a high grain diet. Calves gained weight at a similar rate under either system. Calves produced under the new system required less feed and had leaner carcasses than calves produced under the conventional system. This new system does not require a large investment in facilities and gives producers an option for marketing beef calves in a manner that could increase gross revenues to the total farm enterprise. © 2002 Oklahoma Academy of Science.

| Introduction | Materials and Methods | Results and Discussion | References | Top of Page | Table of Contents | Home |

The southern Great Plains region plays a pivotal role in the US beef production system (1-3). Each fall, young calves born the previous spring on one of more than 500,000 farms across the Southern US are weaned and transported to the central portion of the southern Great Plains. These young beef calves are labeled as "stockers" and are used to harvest the vegetative growth of winter wheat (Triticum aestivum L.). In northern Texas and southern Kansas and the western half of Oklahoma, winter wheat is a dual purpose crop that can be used as pasture for grazing livestock throughout the fall and winter. In the spring, the fields can be allowed to produce a grain crop or to continue to be grazed by livestock (3). Winter wheat is a major agricultural crop in Oklahoma generating $579 million annually in farm receipts (4).

Oklahoma wheat producers purchase weaned calves in the fall at a body weight of about 225 kg. These calves gain from 0.5 to 1.2 kg/d while grazing the wheat fields in the winter and can gain another 50 kg if they graze wheat fields in the spring (3). At the end of the grazing season, calves are shipped to the centralized beef finishing area in the Panhandles of Oklahoma and Texas. Calves are placed in a feedlot and

1Mention of trade names or commercial products in this article is solely for the purpose of providing specific information and does not imply recommendation or endorsement by the U.S. Department of Agriculture.

{Page 28}

fed a high grain diet for 100 to 150 d to increase the quality of the meat. Finished cattle are moved to the local processing plants, fabricated, and shipped to retailers across the US.

Oklahoma wheat producers usually have integrated farming enterprises that include combinations of livestock and forage production systems. Previously at our laboratory, we evaluated three warm season grass livestock production systems currently used in Oklahoma. We found that these systems were economically volatile and that producers needed alternative uses or marketing opportunities for warm season grasses (5). In addition, wheat producers that had purchased calves with good genetic growth potential and had good winter wheat forage production might find that the calves were too large to command a good price in the spring. In an effort to provide a solution to these problems, we proposed that producers could finish these heavy stocker calves on their farms by using a combination of warm season grasses and a high grain diet. The objective of this experiment was to compare this new system of finishing cattle to the conventional confinement system presently being used.

| Introduction | Materials and Methods | Results and Discussion | References | Top of Page | Table of Contents | Home |

This project was conducted over a 2-yr period, and observations were made on a total of 278 calves. Data were collected as part of a larger project to determine the stocker performance of calves of different genotypes that were reared under different environments. This was a multi-state project involving US Department of Agriculture-Agricultural Research Service (USDA-ARS) and state experiment stations in Arkansas and Texas. All procedures used in this study were approved by the Institutional Animal Care and Use Committee (IACUC).

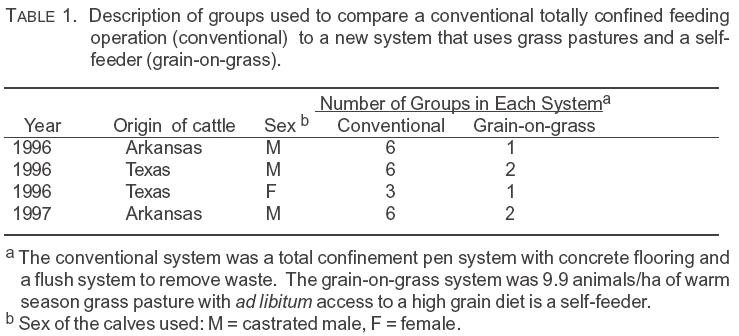

The year in which the data were collected, the origins of the calves, and the number of groups in which calves were fed are shown in Table 1. The experiment was conducted in the summer of 1996 and 1997. All calves from Arkansas were steers sired by Hereford bulls with the dams being either Angus, Brahman, or reciprocal crosses. Details on the type of management applied to these calves and their dams before being transported to El Reno was similar to that described by Brown et al. (6). All of the Texas calves were from the same experimental ranch near Uvalde, Texas. The males were sired by Brahman, Tuli, or Senepol bulls with Angus dams, but the heifers were sired by Limousin bulls with cross-bred dams.

Calves were born in the spring and reared at research facilities in Arkansas or Texas. At approximately 6 to 7 months of age, they were weaned and transported to the USDA-ARS Grazinglands Research Laboratory west of El Reno, Oklahoma. Calves were acclimated to the local climate after arrival, then assigned to graze winter wheat or dormant warm season tall grass native prairie pastures. Calves in the native prairie group were fed a protein supplement

{Page 29}

to promote a daily gain of approximately 0.5 kg. In the spring, all calves from the same source grazed pastures containing cool season annuals. At the end of the spring grazing season, calves were blocked by source and any previous treatments. Within each block, stocker calves were randomly assigned to one of two finishing systems.

Conventional system. For the total confinement finishing system, we used the research feedlots at the ARS laboratory in El Reno, Oklahoma. Pens were located in a 18.5 m x 74 m metal building opened on three sides. One half of the building was divided into 16 pens. The flooring in the pens was concrete that sloped from the front and rear of the pen to the middle. Through normal movement of the calves in each pen all solid waste migrated to the center where it was forced through grating into a gutter. The gutter ran the length of the barn and had a slope of 1%. At 15 to 30 min intervals, 500 L of water was rapidly released into the gutter by a flush tank, and the waste material was swept into a lagoon located adjacent to the building.

Each pen had a capacity of six calves and provided 2.6 m2 of surface area per calf. Pens were equipped with six Calan head gates (American Calan Inc., Northwest, NH) which limited access to each feeder to one calf. Each calf had an electronic key on a neck chain that provided them access to one gate and the corresponding feeder. An adaptation period of 10 d was used to teach the calves which gate they were assigned. A measured amount of feed was added to the feeder daily based on the amount consumed the previous day. Once each week all feeders were cleaned. The residual feed was weighed and discarded. Weekly feed consumption was calculated as the amount fed minus the weekly residual.

Prior to entering the feedlot, calves were treated for internal parasites (Ivomec, Merial Limited, Iselin, NJ) and implanted (Synovex, Syntex Copr., Des Moines , IA). External parasites were controlled by topical application of approved pesticides as needed. Calves were initially fed a diet containing 47.5% alfalfa hay, but the amount of hay was reduced by 10% each week until the diet contained [dry matter(DM basis)] 8.0% ground alfalfa hay, 85.4% ground corn, 1.0% cottonseed meal, 5.0% molasses, and 0.6% limestone. An ionophore (30 mg of lasalocid per kg of diet, Roche Vitamin Inc., Parsippany, NJ) was added. On a DM basis the diet provided 10.6% crude protein, 2.04 Mcal/kg of net energy for maintenance and 1.35 Mcal/kg of net energy for gain.

Grain-on-grass system. The new system was compared to the conventional system described above. Because we used warm season grass pastures rather than pens with concrete surfaces, the new system was labeled "grain-on-grass." Old world bluestem (Bothriochloa spp.) pastures were used in this study. Pastures were 1.6 ha in size and were grazed from early June to early September at a stocking rate of 9.9 calves/ha. Calves were processed as described above prior to being placed on the pastures. Once approximately 80% of the standing forage had been removed, a self-feeder (containing the same diet as that being fed to the calves in the conventional system) was introduced to each pasture. Feeders were 4.6 m long, 2.4 m wide, and 2.7 m tall ("Oklahoma Pride" tandem axle portable self-feeder; Leman's Manufacturing Inc., Chickasha, Oklahoma). Feed was fed by gravity into troughs on both sides of the feeder. Calves had ad libitum access to the diet. Feeders were removed every 3 to 4 days and weighed to determine the amount of feed consumed by the group and then filled with fresh feed. The location of the feeder in the pasture was changed each time it was weighed to reduce the impact of trampling.

A calf was considered to be finished when the thickness of external fat over the twelfth rib was approximately 10 mm. Fatness was determined by visual appraisal by experienced personnel. Once designated as finished, calves were transported to a commercial processor at Amarillo, Texas. Observations on quality characteristics of the carcass were collected on each calf by the Cattlemen's Carcass Data Service (Texas A&M University, Canyon, TX).

The data in this report were analyzed by using the general linear model (GLM) procedure in SAS (7). Feedlot pen (n=21) and grain-on-grass pastures (n=6) were used

{Page 30}

as the experimental unit. The statistical model contained GROUP (df= 3; which was a combination of year, source, and gender; Table 1), FINISHING SYSTEM (df=1; conventional or grain-on-grass), and interaction (df=3) of these two main affects. The residual sum of squares (df= 19) was used to test the three sources of variation.

| Introduction | Materials and Methods | Results and Discussion | References | Top of Page | Table of Contents | Home |

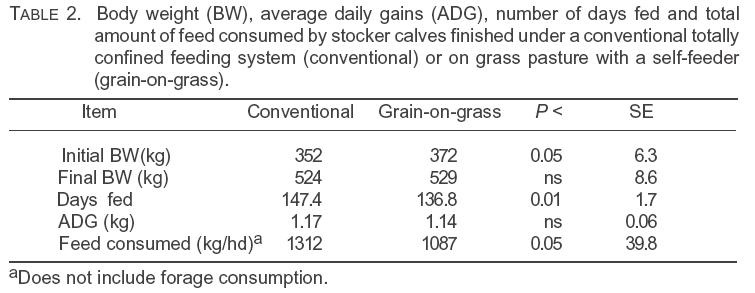

There was no significant group by finishing system interaction, so data are presented by finishing system. Calf performance and the total amount of feed consumed is shown in Table 2. Calves assigned to the conventional system were 20 kg lighter than the calves assigned to the grain-on-grass system at the beginning of the experiment. However, both groups gained weight at a similar rate of 1.16 kg/d. Because calves finished in the grain-on-grass system were heavier at the beginning of the finishing period, they were shipped to the processing plant almost 11 d sooner than the calves finished under the conventional system.

These data on animal performance are similar to other observations made at the El Reno laboratory. Hart and Phillips (8) reported an average daily gain (ADG) of 1.22 kg for heifers fed for 165 d. Phillips et al. (9) reported an ADG of 1.20 to 1.34 for cross-bred calves from the Texas A&M Research Center at Uvalde, Texas. Previous work with calves from the Arkansas herd resulted in initial feedlot body weights of 358 kg and final body weights of 523 kg, which were similar to the present observations. However, average daily gain was 1.45 kg, which was higher than that observed in the present experiment (10). Some variation in feedlot performance is anticipated among years.

The total amount of feed consumed per calf was less (P< 0.01) in the calves fed on grass than for the calves fed in the conventional system (1087 vs.1312 kg, respectively). The lower feed input reflects the contribution of the grass to the total nutrient intake of the calves. We concluded that two factors reduced the amount of feed required to finish calves assigned to the grain-on-grass group. First, these calves were fed for a shorter period of time, and second, during the first 3 wk of the finishing period these calves were harvesting high quality forage from the pastures and not being fed the feedlot diet. Even after the self-feeders were introduced to the pasture feed intake still lagged behind that of the calves in the conventional system for an additional 2 to 3 wk.

Total feed inputs per calf observed in previous experiments at El Reno were 1445 kg (8) and 1252 kg (9). Total feed input is a function of daily feed intake and number of days fed. The greater feed inputs of 1445 kg reported by Hart and Phillips (8) were for calves fed for 165 d compared to that of 142 d in the present experiment.

The equipment needed to process the mixed diet fed in the self feeders used in this experiment are basic pieces of equipment that can be purchased or rented locally. To reduce the need for hay grinding equipment, by-product feeds such as cottonseed hulls and soy hulls, which do not need processing, could be used to replace the hay that was used in this experiment. If adequate amounts of standing forage are

{Page 31}

available, then a diet of 100% grain and no hay could be fed in the self feeder (SW Coleman personal communication).

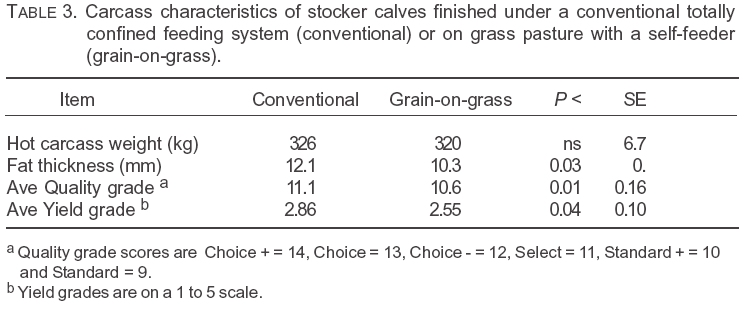

Carcass weights were similar between the two systems (Table 3). Hot carcass weight represents the amount remaining after the hide, head, and internal organs have been removed. The value of the carcass is determined by multiplying the hot carcass weight by price per unit of weight. The price per unit of weight is determined by two measurements that have been established as predictors of the meat quality (quality grade) and the amount of salable product that can be derived from the carcass (yield grade).

A quality grade is assigned to the carcass based on a visual appraisal of the age and the amount of marbling. Age is determined by the degree of ossification of the back bones and the color of the lean meat. Marbling is the degree of fat in the muscle. These factors have been established as indicators of the overall acceptability of the carcass in terms of tenderness, flavor, color, texture, and juiciness. Quality grades are divided into categories (prime, choice, select, and standard) with subunits within each category. For statistical analysis, these categories were assigned the following numerical values: Choice + = 14, Choice = 13, Choice - = 12, Select = 11, Standard + = 10, and Standard = 9. Calves from both systems produced carcasses that fell into the range of 10 to 11. Quality scores in previous experiments at our laboratory ranged from 10 to 12.

When beef calves are first placed in a feedlot, body fat content can be as low as 23%, which is not sufficient enough to produce a carcass with the desired quality characteristics. After calves have been on a high energy diet for appriximately 100 d, body fat content can be as high as 27% (11). The rate at which body fat content increases is a function of age, previous management and genetic type. To achieve a higher quality grade, calves can be fed for a longer period of time.

The second factor in determining the price per unit of carcass weight is yield grade. The yield grade predicts the amount of retail cuts that a carcass will yield. There are five yield grades. Yield grade 1 carcasses have the highest yield of retail cuts, and yield grade 5 has the lowest. As the fat content of the carcass increases, yield grade will increase. Data provided by the Cattlemen's Carcass Data Service (personal communication) reported that the average yield grade on 260,000 beef calves they have evaluated over a 6-yr period was 2.8. In the present experiment, the calves finished under the conventional system had a yield grade of 2.86, while the calves finished under the grain-on-grass system graded 2.55. We have observed yield grade scores of 2.7 (10) and 2.5 (9) in other experiments.

Yield grade is calculated by a formula that considers the amount of external fat, internal fat, weight of the carcass, and the amount of muscling. The calves fed under the grain-on-grass system had less external fat and slightly smaller carcasses than the calves fed under the conventional system.

{Page 32}

This lowered the yield grade. In general, each beef cattle processor develops its pricing structure with a base price for a specific quality and yield grade combination, usually Choice - and yield grade 2. Carcasses that vary from the base are discounted or given premiums. The magnitude of the discounts or premiums is dependent on supply and demand. For example, when consumer demand is high and beef supplies are low, discounts for not meeting the target set by the processor are low. However, when demand is low and supply is high, price differentials are much larger.

In the present experiment, the calves in the grain-on-grass system could have been fed for a longer period of time which would have increased internal and external fat deposits and increased both quality and yield grades. However, extending the feeding period would have increased the cost of production. When the price differential between grades is low, feeding cattle longer to increased the quality and yield grades may not be economically sound.

Cattle finished under the grain-on-grass system proposed in this experiment can be marketed directly to large packers located in the Texas and Oklahoma Panhandles and in Kansas. Each processor will purchase cattle without visual inspection or a bid price with the understanding that a formula will be used to determine the value of each animal after it is harvested. This is known as formula or grid pricing and the formula or grid used varies with each processor. Extension publications from Oklahoma State University are available to educate producers about formula and grid pricing (12) and the seasonal variability in both feeder and finished cattle prices (13-16). Producers that elect to use this marketing option must be able to visually appraise or used indirect measurements to determine the degree of finish in live cattle in order to market them at the proper time.

Another marketing option is to sell cattle directly to the consumer for processing locally. Many consumers want to purchase finished beef directly from the farm to avoid potential contamination of the finished product as it goes through a large high volume processing plant. Producers could use the grain-on-grass system to meet the growing niche market for beef produced under environmentally friendly management and without the use of antibiotics or hormones to enhance growth. This type of beef can be marketed directly to the consumer or to a restaurant that wished to retail organic or free-ranged beef product. Under a direct marketing scheme, quality grade becomes less important than under formula or grid pricing. Under the latter, carcasses are processed shortly after harvesting and do not have time to age to increase tenderness. Processors depend heavy on quality grades to predict tenderness. Under local marketing, processing can be delayed for 7 to 14 d to allow the carcass to age. Aging allows a leaner carcass of a lower grade to become more tender.

Although we did not conduct an economic analysis using these data, the grain-on-grass system had lower feed inputs than the conventional system. Feed is the major cost in finishing cattle and reducing feed cost will reduce cost of production. The grain-on-grass system also affords an opportunity for the producer to market warm season grass and superior animal genetics through an innovative venue. When developing an economic analysis of the grain-on-grass system, the producer should calculate the value of the nitrogen (N) in the animal waste that is distributed across the pasture each day. Based on the amount of feed consumed by the animals in this experiment and after an accounting for losses due to volatilization, we estimate that about 73 kg of N were deposited per ha during the feeding period. This organic N was valued at $0.66/kg or $43.80/ha.

From these data, we concluded that stocker calves that might be considered too heavy to be marketed effectively in the spring can be finished on the producer's farm without constructing any feeding facilities and with minor capital investment. Warm season grass pastures that may have low economic return potential can be used to provide nutrients early in the finishing period which will decrease the amount of feed needed. Calves finished on grass

{Page 33}

pastures yielded acceptable carcasses for the beef processor with less internal and external fat and eliminated the expense of disposing of the animal waste generated by confinement feeding operations.

This project was funded in part by an Oklahoma Applied Research Support Grant through the Oklahoma Center for the Advancement of Science and Technology and through a Specific Cooperative Agreement (6218-31630-003-02S) between the USDA-ARS Grazinglands Research Laboratory and Redlands Community College. We are grateful for the cooperation of Arkansas, Texas, and Oklahoma Agricultural Experiment Stations.

| Introduction | Materials and Methods | Results and Discussion | References | Top of Page | Table of Contents | Home |

1. Jones OR, Johnson WC. Cropping practices: southern great plains. In: Dregne HE, Willis WO, editors. Dryland Agriculture, Agronomy Series No. 23. Madison(WI): ASA-CSSA- SSSA;1983. p. 365-385.

2. Phillips WA. Use of manure on grazing lands. In: Hatfield JL, Stewart BA, editors. Animal Waste Utilization: Effective Use of Manure as a Soil Resource. Chelsea (MI): Ann Arbor Press; 1998. p.157-171.

3. Phillips WA, Rao SC, Dalrymnple RL, Klepper EL. Annual cool season grasses. In: Moser LE, Buxton DR, Casler MD, editors. Cool-season Forage Grasses. Madison (WI): ASA-CSSA-SSSA; 1996. p. 781-802.

4. Oklahoma Agricultural Statistics. Oklahoma City, OK: Oklahoma Agricultural Statistics Service; 1997. p. 16.

5. Phillips WA, Coleman SW. Productivity and economic return of three warm season grass stocker systems for the Southern Great Plains. J Prod Agric 1995;8:334-339.

6. Brown MA, Phillips WA, Brown Jr. AH, Coleman SW, Jackson WG, Miesner JR. Postweaning performance of calves from Angus, Brahman, and reciprocal-cross cows grazing endophyte-infected tall fescue or common Bermudagrass. J Anim Sci 1999;77:25-31.

7. SAS/STAT user guide release #7.0.Cary (NC): SAS Inst, Inc;1998. p. 549-640.

8. Hart SP, Phillips WA. Wheat straw, ammoniated, wheat straw and alfalfa hay as roughage sources in a finishing diet for heifers. Nutr Report Intl 1986;34: 465-471.

9. Phillips WA, Holloway JW, Coleman, SW. Effect of pre- and post-weaning management system on the performance on Brahman crossbred feeder calves. J Anim Sci 1991;69:3102-3111.

10. Phillips WA, Brown MA, Brown Jr. AH, Coleman, SW. Genotype X environment interaction for postweaning performance in crossbred calves grazing winter wheat pasture or dormant native prairie. J Anim Sci 2001;79:1370-1377.

11. Coleman SW, Gallavan RH, Phillips WA, Volesky JD, Rodriguez S. Silage or limited-fed grain growing diets steers: II. Empty body and carcass composition. J Anim Sci 1995;73:2621-2630.

12. Ward CE, Schroeder TC, Feuz DM. Grid pricing of fed cattle: Base prices and premium- discount grids. Stillwater, OK: Oklahoma Cooperative Extension Service; 1999. F-560. Available from Oklahoma State University.

13. Bliss TL, Ward CE. Seasonal cattle feeding profits. Stillwater, OK: Oklahoma Cooperative Extension Service; 1989. F-506. Available from Oklahoma State University.

14. Peel DS. Oklahoma City stocker and feeder steer prices, 1975-1995. Stillwater, OK: Oklahoma Cooperative Extension Service; 1995. CR-544. Available from Oklahoma State University.

15. Peel DS. Oklahoma City stocker and feeder heifer prices, 1975-1995. Stillwater, OK: Oklahoma Cooperative Extension Service; 1996. CR-545. Available from Oklahoma State University.

16. Peel DS. Using seasonal price patterns to improve feeder cattle marketing decisions. Stillwater, OK: Oklahoma Cooperative Extension Service; 1992. CR-529. Available from Oklahoma State University.

Received: March 18, 2002; Accepted: August 23, 2002